In-depth research on clamping techniques has always been an important proposition in CNC machining. Under the continuous bar clamping and bar cutting practice, CNC machine manufacturers have constantly innovated and introduced various types of collet chuck.

In this article, whatever it is first operation for bar clamping or second operation for finished part,we will focus on clamping techo and provide a comprehensive description and comparison of the three most common types of collet chuckscurrently available on the market.

In this particular style of clamp tooling, push-forward collet nose and hood come together in a converging manner towards the right. The section of the collet chuck that is tightened is pushed into the corresponding draw of the hood to securely hold the component in place. As the collet is pushed to catch and clamp, there is a slight tendency for the bar to be pushed outward. By having the bar held against a stop bar located on the turret head, this slight outward movement guarantees precise adjustment of the machining length.

So, we also called push forward collet as push out collet. Sometimes, people also call dead length collet as ‘push out collet’, but for dead length collet, what is be pushed out is the sliding sleeve not the collet itself. You will understand more while you continue to read, we will expand from the description of dead length collet.

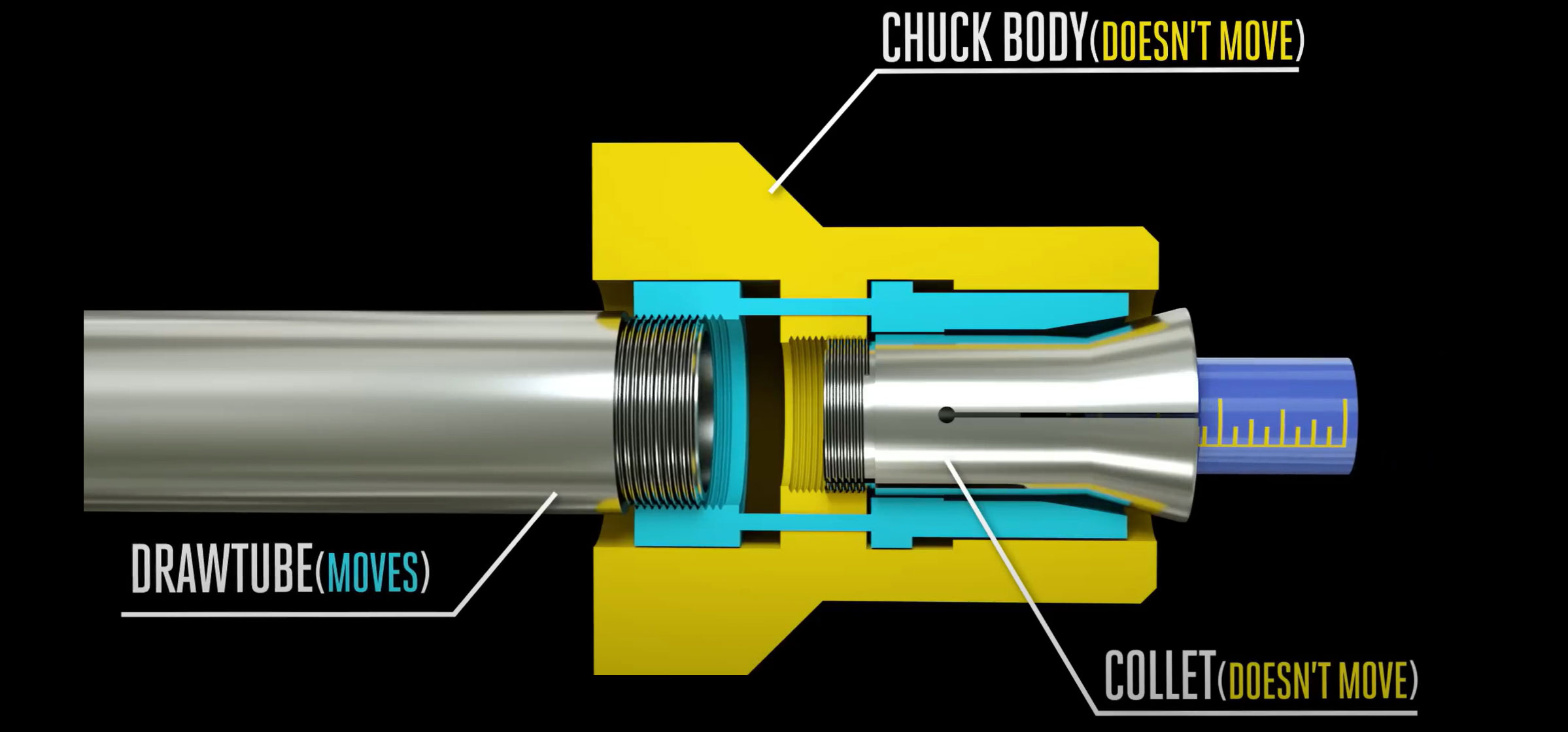

In pull back to close system, we can see typical pull-back stype collet(draw in collet), like 5C,16C collet for grinding machine or EDA-6,8,10 swiss type collet for Eguro sliding head lathe.

With this style of collet chuck,our collets are pulled back by the draw tube, mostly will have external or internal thread where often screw directly to our draw tube adapter which is tightened onto the draw tube.As a collet is drawn back,the collet is forced closed against our stock by the matching angle on the chuck body.

Whatever pull back or push forward collet,any variance in our part’s diameter will cause a proportional shift in our part z-axis position because of the collet moving with the draw tube or any other accessories. For a first operation the slight z-variance is accepted,we can just only need to add in an extra facing pass, but on a second operation it does matter because that is our finished part length.

Therefor, A dead length collet chuck is more appropriate for those second operation,like 145e(tf25),138e(tf20),1536e(tf37),173e collet which under DIN6343 standard,mostly using in swill style sliding head CNC lathe. Like Citizen,Tornos,Star,Nomura,KSI,Maier,More machine you can check : Machine Ref.

Dead length collet also belongs to push to close system, that is why some customer might would like to call them as a ‘push out collet’,especially when they order 173e collet. However, it have some different with push-forward collet,when the collet be closed, the part z-location will keep the same, that is why it is called by dead-length collet,or accu-length,true-length,fixed-length.

Now,you can get why the swiss style micro lathe called Sliding head machine. The key point is slide sleeve and the high accuracy position for second operation.And it might will have sub-spindle for picking up finished part,also might have guide bush for holding the bar,more about sliding head machine, we will expand it next time.

Push Forward Collet

Advantages

Disadvantages

Pull Back Collet

Advantages

Disadvantages

Dead Length Collet

Advantages

Disadvantages

So, which type collet your were using, and which types of collet chuck you prefer to?

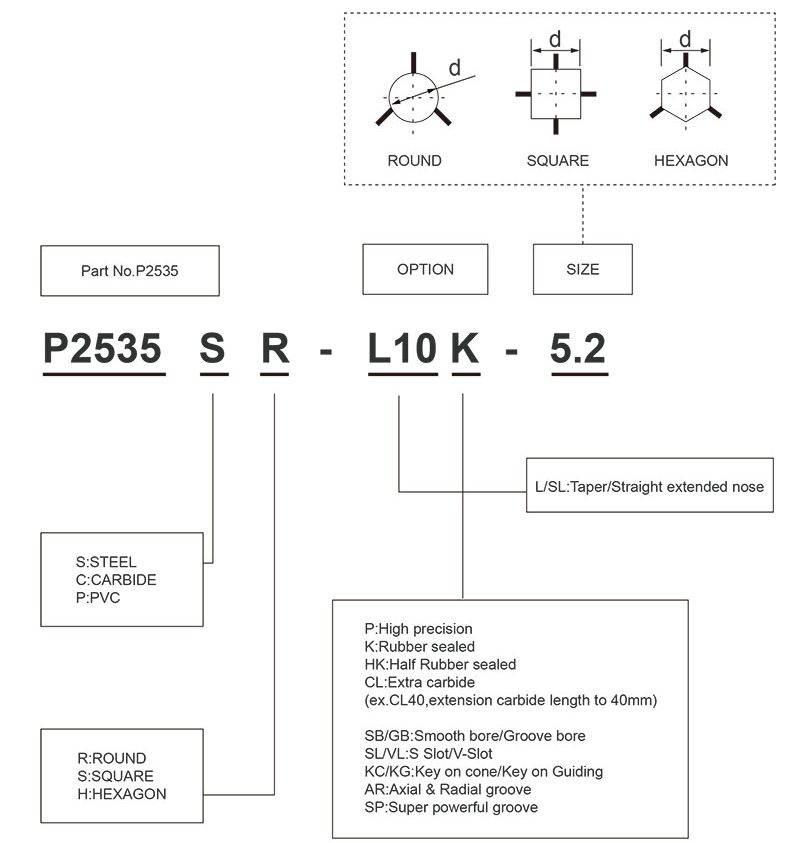

Pls check Part No written method as per...

This July, we will set to host a important visit from our Indian...

©2023 Shenzhen Zeling Precision Industry Co., Ltd. All rights reserved