What is a Guide Channel?

The Guide Channel is the core guiding component of a bar feeder, made of wear-resistant polyurethane (PU). Installed at the feeder’s outlet.

It act a role as per below

- Precisely guides bars raw into the spindle (ensures straight feeding, prevents deflection)

- Reduces vibration & noise (absorbs harmonic oscillations during high-speed feeding)

- Protects bar surfaces (prevents scratches for better machining finish)

Five Key Advantages of PU Guide Channels

- High Wear Resistance: Exceptional durability

- Scratch Prevention: Elastic cushioning protects bar surfaces

- Vibration & Noise Reduction: Lowers noise by 30%+

- Oil Resistance: Resists cutting fluid/lubricant corrosion

- Cost-Effective: Low replacement cost

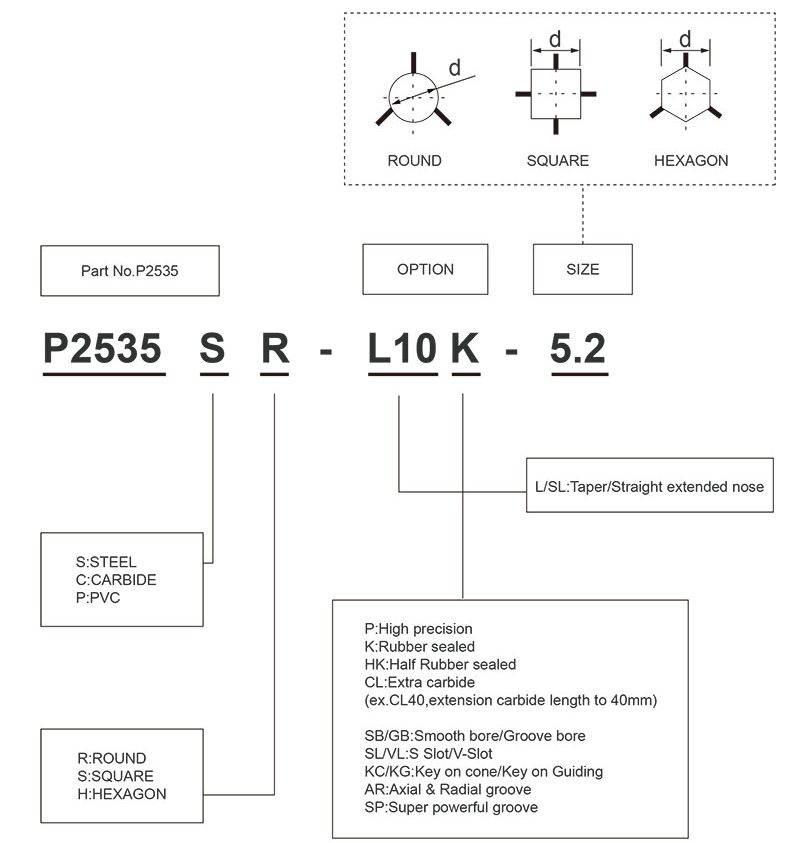

Popular Bar Feeder with compatible Guide Channel Sizes

How Guide Channels Master Dynamic Precision

- Straightness

– Standard: ≤0.02mm/100mm (laser-calibrated)

-Impacts:

Bar deflection → Poor concentricity (e.g., H6→H7 tolerance loss)

Uneven wear

- Clearance Control

-Ideal clearance:Bar diameter + 0.05~0.2mm

Too large: Bar wobble → Accuracy issues

Too small: Feeding resistance

- PRECOLLET Guide Channel’s Lifespan Secret: Laser-Textured Micro-Surface Technology

-Laser-etched micro-pockets store lubricant

-40% longer lifespan vs standard PU

Additional Resources